Held for checking stock status

In OrderFlow 4.4.0 we’ve introduced further improvements in dealing with error scenarios, such as short picks. Here, we’ve added a new ‘held for check’ stock status, which can be used at the point where a short pick occurs. The aim is to be minimally disruptive, so that if the initial stock position turns out to have been correct, any other picks that rely on this stock can be carried out as before.

Accompanying this change, we have added a new dashboard as well as a handheld rolling stock check, which targets the locations with stock held for checking. These features help to allow the necessary follow up stock checks to occur soon after the initial problems have been identified.

Global batches

Picking batches in OrderFlow were originally channel-scoped, and more recently, the ability to pick shipments from multiple channels within the same organisation was introduced. With OrderFlow 4.4.0 we offer the capability to pick shipments across multiple organisations.

This feature can be useful in particular for 3PLs with smaller clients for which the order volumes do not allow for efficient organisation-specific batches. This applies, in particular, close to the cut off for end of day courier collection, where only a few orders may need to be picked.

If automated batch creation is enabled, the system can apply a script to determine whether global batching should be used. This allows for example for organisation- or channel-specific batches to be used for most of the day, with global batches used closer to the end of day cut off.

Note that there are some restrictions on the use of global batches, so please contact us for further information on these.

Shipment assignment

A small but potentially consequential change introduced in OrderFlow 4.4.0 relates to the timing of order line assignment. In previous releases all the lines for a multi-line order had to be in stock before the system attempted to assign specific picking locations to any individual order line. From 4.4.0, it is possible to allow for assignment to take place on any in stock order line, even when other lines in the shipment are out of stock.

This approach can be used to allow the system to more effectively reserve specific stock for order lines on a first come first served basis.

Deassignment following status changes

With this release we’ve also refined the effect of changing the status of stock on existing order lines. Some may recall that in a recent release, we introduced non-invasive deassignment following stock quantity adjustments. With OrderFlow 4.4.0, the same feature now applies for stock status changes, with the system attempting to find alternative picking locations if necessary, then falling back to creating back orders, only deassigning stock from order lines if neither of these two options apply.

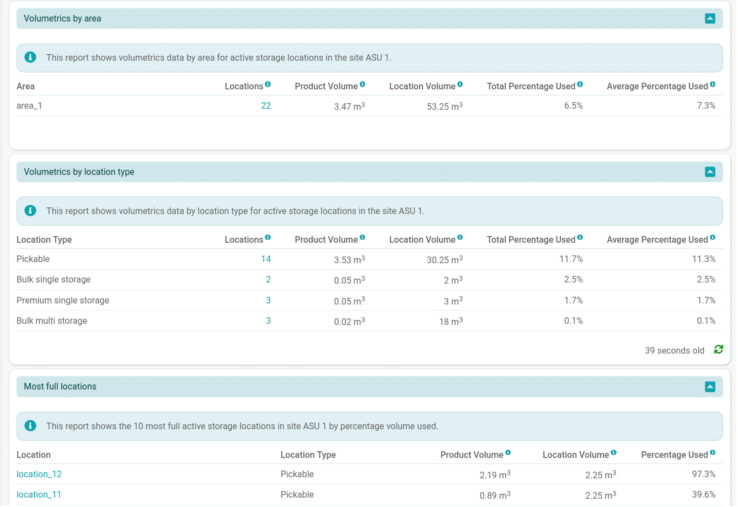

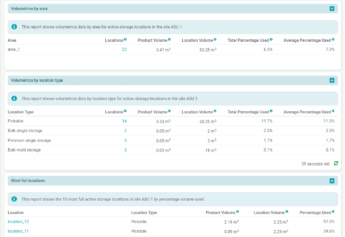

Volumetrics dashboard

With 4.4.0 we’ve introduced a dashboard to make the volumetrics data recorded in OrderFlow more visible to users. Example output is shown below.