The measurement process can automatically recalculate the remaining quantity or require the operator to confirm the remaining quantity and calculate any wastage. Alternatively the module can support integration with industrial scales or other hardware used in the measuring process. The module also allows the intelligent handling of small ‘remainder quantities’, for example by earmarking small lengths of fabric left on a roll for use as samples rather than returning them to general stock.

As well as fulfilling customer orders directly the Measurement module can also be used to drive the production of stock items, allowing users to measure out consumer quantities from a bulk container or cut a whole wheel of cheese into wedges. The works order instruction to generate required items can be received from an external source through an API or can be triggered by processes within OrderFlow.

The system supports automatic label printing of barcode labels to identify the items being produced and maintain the end-to-end audit trail of lot tracked products.

Courier Integration & Shipping

This release adds new courier integrations and improves the handling of multi-package shipments across OrderFlow’s shipping functionality.

FedEx integration has been enhanced with a comprehensive onboarding mechanism that streamlines the setup process for new FedEx accounts. This includes support for the FedEx Ship API, with specific improvements to ZPL label printing for shipments containing multiple packages. The system now correctly generates individual labels for each package within a multi-package FedEx shipment.

etail-USA has been added as a new courier integration, providing an additional shipping option for US-based operations. This integration follows OrderFlow’s standard courier integration patterns, supporting label generation and tracking number capture.

InPost courier integration has been implemented, adding support for this European parcel locker network. The integration enables OrderFlow to generate InPost labels and manage InPost-specific shipping requirements.

These additions increase the range of shipping options available to operations teams, while the multi-package improvements ensure accurate label generation regardless of which carrier is selected.

Licence Plate Management

Extensive enhancements to licence plate functionality address the operational complexities that arise in licence plate-driven warehouse environments.

Mixed storage methodologies have been enhanced, improving the handling of facilities that use both direct location storage and licence plate storage simultaneously. The enhancements address specific edge cases and improve the consistency of stock tracking when products move between direct and licence plate storage approaches. Licence plate removal capabilities have been added to handle situations where licence plates go missing or need to be removed from the system.

Location validation has been improved with check character verification, helping to prevent errors when pickers manually enter target location codes.

Returns processing for licence plate-held stock has been enhanced to handle the specific requirements of returning goods that were originally picked from licence plates. The system maintains proper stock tracking throughout the returns process.

Order Merging

OrderFlow now includes functionality for combining multiple orders and shipments destined for the same customer. The system evaluates pending shipments and identifies opportunities for consolidation based on configurable business rules. Once suitable candidates are identified, the system can merge multiple shipments into a single consolidated shipment, updating all related order lines and allocation records accordingly.

The user interface provides the ability to manually trigger combination operations for specific shipments. This gives warehouse supervisors control over when consolidation occurs, allowing them to balance the benefits of reduced shipping costs against the operational preference for processing orders quickly.

Picking Operations

Significant enhancements have been delivered to streamline warehouse picking processes, improve error handling, and add flexibility for advanced picking scenarios.

A new picking mechanism intelligently handles two scenarios: picking raw stock from a location directly into a licence plate (creating the licence plate during the pick operation), or alternatively, picking an already-existing licence plate whole. This dual-mode capability provides greater flexibility in warehouse operations, particularly when stock can be stored either as loose inventory or pre-palletised on licence plates, allowing pickers to handle both situations seamlessly within the same workflow.

For operations using totes in flow-through or push-through racking, the system now handles missing stock situations more intelligently. When a picker encounters what appears to be missing stock at the expected location, the system automatically checks whether replacement stock exists elsewhere that could fulfil the pick. If replacement stock is available, the picker is directed accordingly. If no alternative stock exists, the picker is given the option to skip the line rather than being stuck in an unresolvable situation. This reduces time wasted searching for unavailable stock and keeps picking operations flowing smoothly in high volume flow-through environments.

Pickers can now modify task locations to switch between different product lots during picking operations. This flexibility allows pickers to adapt to actual stock locations whilst maintaining proper lot traceability.

OrderFlow now allows for a generated PDF documents for picked shipment licence plates, creating a comprehensive record of all items picked onto each licence plate.

Order Processing

Orders can now be picked in advance for future despatch dates, allowing warehouse teams to balance workload across shifts and plan ahead for known busy periods or scheduled deliveries.

Operations now have better control over when courier validation checks occur during the shipment workflow, allowing validation timing to be configured for the most appropriate stage. Improved recovery options help resolve situations where shipments have entered unexpected states due to courier validation issues, providing clear paths to fix problems and preventing shipments from becoming stuck.

Shipment Batching

The new shipment batch screen has been completely reworked to deliver significantly faster performance when creating and managing pick batches. Loading times have been reduced, particularly noticeable when working with large batches containing hundreds of shipments.

Batch operations now support seamless switching between different picking and packing modes at various stages of the workflow. Warehouses can choose between individual picking with scanning verification and bulk picking without scanning, as well as between individual packing with scanning and bulk packing approaches. This flexibility allows operations to match the workflow to the specific requirements of each batch, switching modes as needed based on product characteristics, order urgency, or operational constraints.

System Performance

Various enhancements deliver significant performance improvements across search, page loading, login processes, and query execution.

Multiple search operations have been optimised to deliver faster results. Schedule execution searches now use more efficient handler-based filtering, whilst product and location searches benefit from new database indexes that accelerate stock change queries.

Search behaviour has also become more intelligent, automatically disabling slow wildcard searches when they would cause performance issues, ensuring the system remains responsive even when handling complex search criteria.

Behind-the-scenes optimisations have been added to reduce overall system resource consumption. Login and scheduled job execution processes now cache channels, organisations, and sites to reduce database queries during authentication. These changes reduce server load and database pressure, particularly beneficial during peak usage periods with many simultaneous users or frequent automated processes.

The system now prevents potentially slow text-based searches when date ranges haven’t been specified. This protection mechanism ensures that searches using partial text matches must include appropriate date restrictions, preventing database performance issues caused by unrestricted searches across large historical datasets.

Product and Inventory Management

For order lines where a specific product lot must be used, the system now automatically resets lot assignments when that stock becomes unavailable. The system can then reassign order lines to an available alternative lot, keeping orders moving through the warehouse without manual intervention.

Dangerous goods information is now displayed more prominently throughout the system, including specialised display during packing operations for custom quantity orders. This ensures warehouse staff have immediate visibility of hazardous material requirements when handling dangerous goods, supporting compliance with shipping regulations and safety requirements.

Order Entry

Manual order entry has been significantly enhanced to capture more shipment detail and provide greater flexibility during order creation. Users can now select product lots from a dropdown list rather than requiring barcode scanning—particularly useful when creating orders at a desktop or when barcodes aren’t immediately available.

The order entry screen now captures key shipment fields including third-party references, delivery time slots, and delivery instructions directly during order creation, eliminating the need to switch between screens or edit orders after creation.

Goods Receipt and Putaway

The goods receipt process now allows warehouse staff to upload and view the documentation received with incoming deliveries, eliminating the need for paper filing or external document storage.

During the booking-in process, the system now provides enhanced warnings to alert staff to important conditions or requirements before goods are processed.

When selecting putaway locations, the system actively validates storage location restrictions in real-time, preventing incorrect placement of stock and ensuring compliance with warehouse zoning rules (such as temperature zones, hazardous goods areas, or customer-specific storage requirements).

Temperature-controlled Despatch

Temperature-sensitive shipment handling has been significantly enhanced with intelligent postcode-based heat-hold controls.

Products can now have different temperature sensitivity settings for storage versus despatch, providing greater flexibility for items that require cold storage but can tolerate ambient temperatures during short delivery periods, or vice versa.

OrderFlow can now import UK weather information that give postcode level temperature data and hold the despatch of temperature-sensitive shipments when the target destinations are experiencing high temperatures.When shipments are held in this way, Customer Services teams can be automatically notified via email, enabling proactive customer communication about delivery delays.

Returns

The returns process has been enhanced to provide greater flexibility and efficiency when handling customer returns.

Warehouse staff can now process returns for items that were despatched as part of bundles or kits, even when those individual components weren’t sold separately – ensuring accurate inventory reconciliation regardless of how products were originally ordered.

During returns processing, staff can now specify exactly where returned stock should be placed as they’re processing each item, rather than having to make separate putaway decisions afterwards. This streamlines the workflow and ensures returned goods reach their correct destination immediately – whether that’s back to general picking stock, a quality inspection area, or a dedicated returns location.

For warehouses using pallet management systems, the returns process now fully integrates with pallet-based storage, making it seamless to return products that were originally picked or stored on pallets.

Other Enhancements

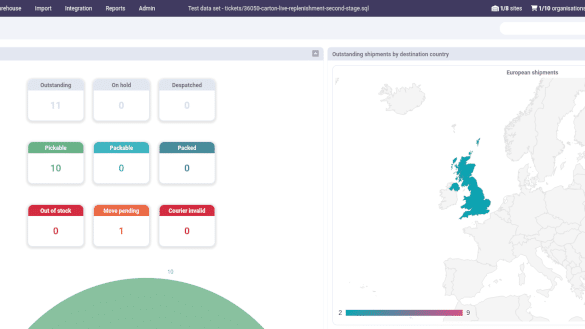

This summary covers the most significant operational enhancements, but the releases also include improvements across several other areas: enhanced dashboards providing better visibility of warehouse operations; API and integration refinements improving data exchange with external systems; commercial invoice management and pricing enhancements; improvements to work order processing; and various data import and security enhancements.

If you’d like to discuss how these enhancements might apply to your warehouse operations please get in touch.