The first few months of 2025 has been another busy period for OrderFlow, both in terms of customer projects as well as developments to the software platform. During this period, we’ve brought out four new OrderFlow releases, starting with 4.4.7 in January, going through to 4.5.0 at the end of April, in the process introducing some exciting and potentially useful features. We’d like to bring you up to date with some of these changes.

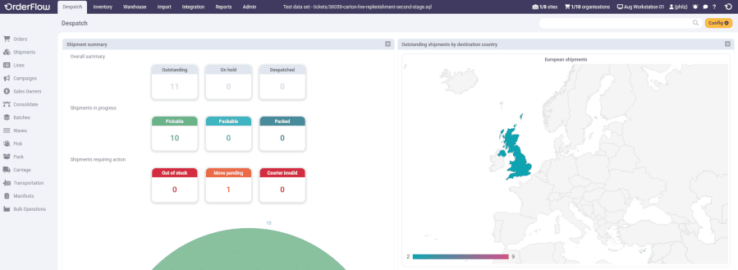

New OrderFlow theme

Over the last few months we have continued to refine our updated design for the OrderFlow desktop application, with a more responsive page layout, more efficient use of screen space, and an updated look and feel that matches our OrderFlow branding. This theme is now available for use in OrderFlow 4.5.0. From OrderFlow 4.5.1 we will be switching over to the use the new theme by default. However, for the next few releases you will still be able to revert to the old theme, either on a per user basis or across the system as a whole.

Mobile Interface

With the latest OrderFlow 4.5.0 release we are relaunching the OrderFlow mobile interface, doing away with the need to install a dedicated Android or Apple iOS app. Instead, we allow customers to send their clients or users an invitation link via SMS, providing for a browser shortcut to OrderFlow that can be installed directly on the device home screen.

The mobile interface provides read only access to key OrderFlow dashboards, and can easily be customised via configuration to meet varied information reporting needs.

Shopify GraphQL API

OrderFlow 4.5.0 supports integration with the new Shopify GraphQL API. This API is much more flexible and efficient than their legacy REST-based API, allowing for clients such as OrderFlow to access the specific data they need, with fewer API calls and reduced data transfer.

Picking from Flow Racking for lot tracked products

We’ve added the ability to pick lot tracked SKUs from licence plates contained within flow racking. Flow racking allows for very efficient picking location space utilisation, and physical enforcement of FIFO behaviour but introduces significant complexity for lot tracked SKUs. OrderFlow now supports dynamic order line stock reassignment to cater for corner-case exceptions without compromising the integrity of warehouse lot tracking.

Replacement of damaged stock at pack time

We’ve added a feature that allows damaged stock to be replaced during the packing of a shipment. Typically damaged items are identified during receipt or stock checking. However, if an item is damaged during the picking or packing steps OrderFlow now supports a mechanism that allows it to be substituted during the packing process.

Alternative picking locations during short pick

For some time, OrderFlow has been able to suggest alternative pick locations if a picker selects the UNAVAILABLE button during a handheld shipment pick. Until recently, this feature has not been supported for the SHORT button (where the picker was able to pick some but not all of the required stock from the source location).

Alternative pick locations can now be suggested for both UNAVAILABLE and SHORT picks

Support for partial reassignment

A related feature is the ability to make a partial order line reassignment following a negative stock adjustment. Previously, if a shortfall in an assignment was identified, a reassignment would only be possible if another location contained enough free stock for the whole assignment.

For example, if only 3 of the 5 items required for a product turned out to be present in the current location, then reassignment would only be possible if another location contained 5 of the product.

The assignment of 3 in the original location can now be retained, requiring only 2 to be present in the alternative location. This reduces the likelihood of reassignment not being possible when there is free stock available, but only in small quantities.

Licence plate improvements

We’ve continued to make improvements in the display of licence plates in OrderFlow. It’s easier to see the history a particular licence plate’s movements between nesting locations and to see the detail of all the licence plates that have been nested in a particular location.

We’ve added some refinements to the way licence plate stock is handled in imports and tightened up the restrictions on stock movements to licence plates that contain stock for access-restricted organisations.

Unit of Measure toggle during packing

While full use of Units of Measure (UOM) functionality in OrderFlow provides a powerful solution for managing stock held as loose items or in cases, it does involve some operational complexity and overhead. OrderFlow also allows UOMs to be used in more limited ways, the most recent example being that of a UOM toggle during packing.

This optional feature allows the operator performing a scan to pack to indicate that the items being packed are cases (and not pieces). Rather than simply counting and entering the quantity being packed, the operator verifies product quantities by scanning cases, with each product scan incrementing the counted quantity based on the case quantity for the product.

New hybrid report with handheld pick

OrderFlow supports a new flavour of picking. While most customers use handheld picking to scan each of the items being picked, it is now also possible to use a paper based report in conjunction with a handheld.

The paper picking report can be printed automatically, the pick can then be started using a warehouse handheld to scan the cart or tote the items will be picked into. However, instead of then scanning each product, the operator can use the paper report to identify alternate source locations for the items they need. Confirming the picking has been completed on the handheld moves all the required stock into the mobile location.

While this style of picking is not recommended for high value or complex multiline orders, it potentially serves a niche where a time efficient process is required and the risk of picking errors is low.

Mechanism to restrict number of SKUs in a location

With OrderFlow 4.5.0 we’ve added the ability to restrict a storage location to a specified number of products. The appropriate quantity can be set either against a specific location, or against a location type. If the specified quantity is already present in the location concerned any attempt to add additional stock will be rejected with a suitable error message.

Better behaviour when stock is ‘held for check’

The ‘held for check’ stock status is used in OrderFlow environments that do not want to automatically apply stock adjustments in the event of a short pick. Instead a suitably qualified user can be directed to check the location in question. No stock can be moved from the location until the check has been completed.

We’ve made some refinements to the behaviour when the ‘held for check’ status is used. Current order picks can now remain open, but will not be progressed. Once the resulting stock check is completed the related picks can be progressed.

Additional product picking or packing instructions

We’ve added a change that allows picking or packing instructions to be associated with individual products. Depending on the configuration, at the point of picking or packing, the instruction would be presented to the operator to guide them on the required task(s).

Billing changes

We’ve continued to develop billing-related functionality which can be used by OrderFlow 3PL customers to assist in generating invoices for their clients. With OrderFlow 4.5.0 it is possible to set billing periods by organisation, instead of just by billing metric. For clients that receive weekly bills, we’ve also made it possible to configure the start day of the week on a per-organisation basis.

Other Enhancements

With recent changes to OrderFlow we’ve added many other small changes, including some notable ones:

- for handheld picks to subdivided carts, OrderFlow will now show the reference for the picked shipment during each pick

- the daily stock snapshot now includes the stock status as well as other stock information, including stock nesting location and inactive quantity

- it is now possible to directly update the status of stock via the product location import. Previously, only a quantity update was possible

- it is now possible for 3PLs to perform global replenishment tasks, that is, tasks that cover replenishment operations across multiple client organisations

- we’ve added a mechanism to automatically reset the batch type of shipments on a schedule

- we’ve made it easier for customers to set up Two Factor Authentication on a per-user basis.