What is Inventory Management?

Inventory management is the heart of every WMS. At its very simplest inventory management is the process of dividing up your available storage space into distinct locations and then keeping track of stock moves in and out of the warehouse and between locations. Your WMS should also allow you to define the rules that determine how your stock is distributed within the warehouse and keep a record of all historic stock movements.

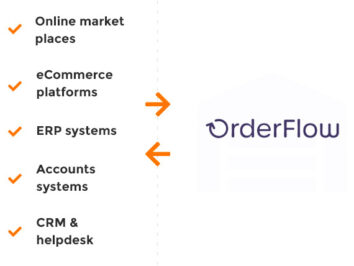

Within that basic requirement ,there are lots of different priorities that can often conflict with one another. The need to use space efficiently, the need to minimise the distance travelled whenever stock is moved, the physical nature of the items and a host of other factors will all play a part in determining the optimal design of the business rules that control the management of stock in your operation. The way all the different constraints and priorities interact usually means that the best approach in one warehouse is not going to work well in another. Read how a smart WMS, like OrderFlow, can increase your warehouse and fulfilment efficiency.

Inventory Management Software

OrderFlow provides a range of tools that allow us to deliver the optimal solution for your warehouse operation. Some of the key elements of the design are described in more detail below:

Advanced Inventory Management

Space utilisation

Warehouse space is expensive and most operations find it’s in short supply, particularly pick face locations that are accessible from the ground. If you capture the dimensions of your warehouse locations and the dimensions of your products OrderFlow will start to track the space used and the remaining space available, feeding this into the initial stock putaway, stock replenishments and all other stock movements.

OrderFlow can match the volumetric data about the stock that needs to be put away or moved into the pick face with the space available in the target locations to ensure the optimal location is selected.

SKU characteristics and SKU velocity

The nature of the item may play a large part in determining the valid target locations for it. Most obviously if you have ambient, chilled and frozen areas of your warehouse you need to be able to restrict different product categories to the appropriate areas. Within an area you might want to ensure heavy or potentially unstable SKUs are always held at ground level, ensure that loose items are held in suitable bins while others go on appropriate shelving.

SKU velocity is a measure of how frequently a particular SKU is picked. OrderFlow can ensure that high velocity SKUs are held in the most easily accessed locations or ensure that they are held in multiple locations spread across in different aisles.

Tracking product lots

OrderFlow provides a flexible framework within which the product lot (or batch) information for some SKUs is captured on receipt and then associated with the relevant items as they move through every warehouse process. Other SKUs might just require the user to capture a lot reference or unique serial number at the point the item is added to an outgoing customer shipment.

Detailed lot tracking can impose significant restrictions on the operational processes within a warehouse, which can hinder operations in busy periods such as Black Friday. OrderFlow makes these transparent to the users and ensures the integrity of the lot tracking process for food manufacturing and other sectors where traceability is critical.

Read more about product lot tracking, expiry dates, batches, and serial numbers with WMS

Tracking units of measure

There can be significant benefits of being able to default different warehouse operations to the most appropriate unit of measure relevant to the SKU. As an example, a SKU might need to be sold individually but always be received into the warehouse in cases that contain six cartons, with each carton containing twelve items. You might want to capture case quantities on receipt, replenish the pick face in carton quantities but always require your pickers to confirm the pick of individual items.

OrderFlow can support situations where all the different units of measure are identified by the same barcode and situations where each UoM for a SKU is distinguished by a unique barcode, making it easy to infer the quantity from the barcode value being scanned.

Supporting multiple units of measure can make warehouse moves more efficient but it becomes essential in environments that need to support both trade and consumer orders. Consumer orders are generally for item quantities, while trade orders often require full cases. OrderFlow is able to support situations where some trade orders specify the case quantities required and others may specify unit quantities, requiring OrderFlow to round the quantity to be picked up or down to avoid the need to break cases.